The Most Durable

Heavy Load Transport

on the Market

Air Caster Solutions Provider

for Fortune 500 Companies

& Industrial Manufacturers

The Technology of Air

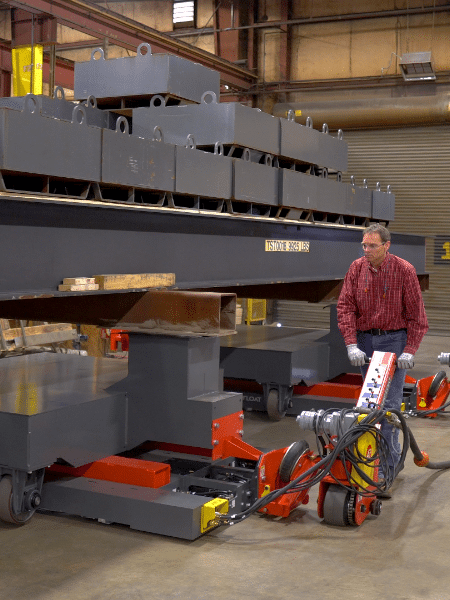

We exist to create material handling solutions for moving and positioning heavy and difficult to position loads with low friction, omnidirectional movement.

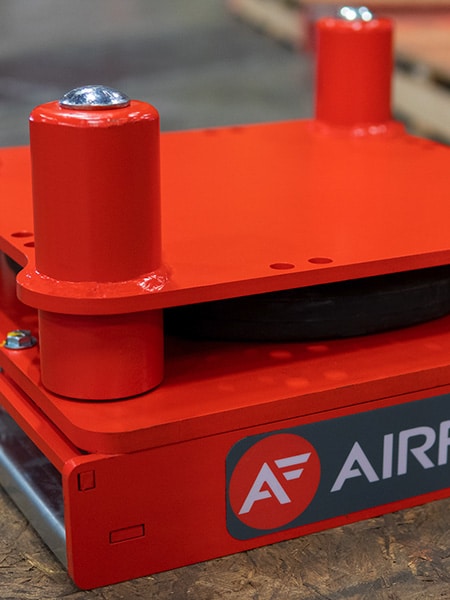

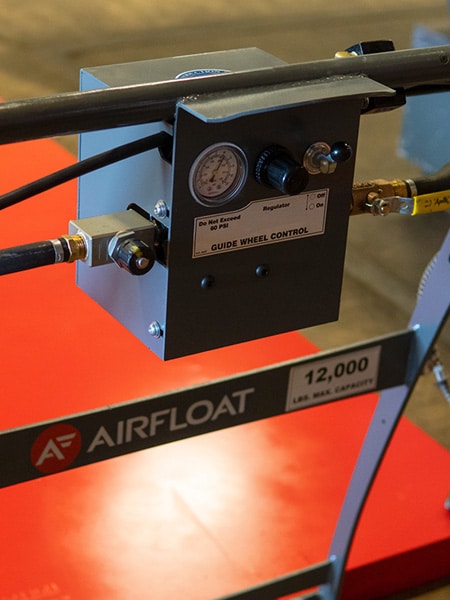

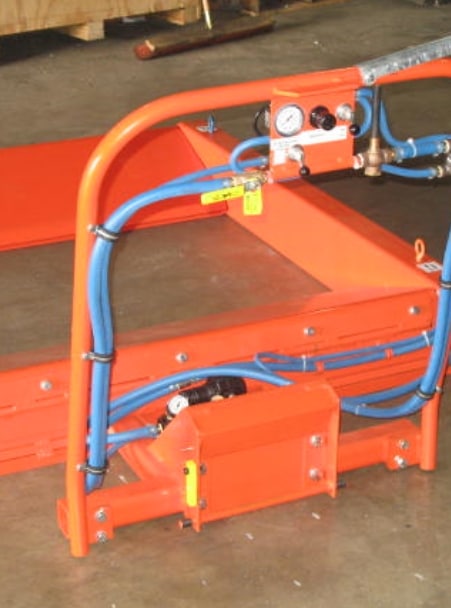

The Air Caster is a pneumatic device that forms a lubricating film of air between the load and floor surface, similar in principle to a hovercraft or an air hockey table. We provide material handling products and solutions for heavy loads when frictionless, omnidirectional movement is critical.

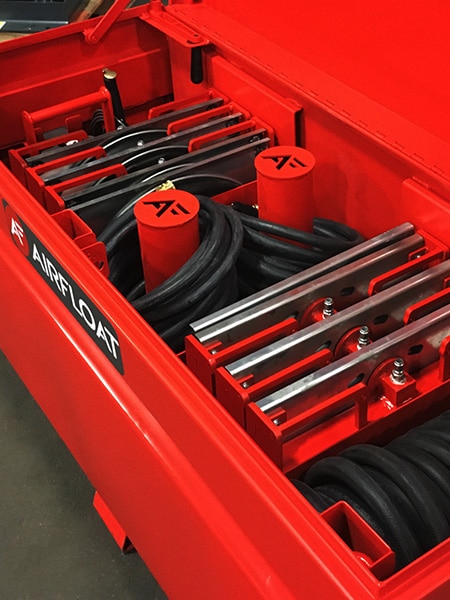

Our Air Caster Product Suite

LOOKING FOR A CUSTOMIZED SOLUTION? WE DO THAT TOO.

REQUEST A FREE CONSULTATION

RESOURCES

View our library of in-depth content including case studies, product videos, user manuals, and technical drawings.

View Resource Index

Case Study

ArcelorMittal Uses Airfloat to Change the Way They Assembled Backup Chocks

Case Study

Bombardier uses Airfloat to Modernize their Commercial Jet Manufacturing Facility

Case Study

Case New Holland Uses Airfloat to Improve How They Manufacture Grain Headers

FROM AIRFLOAT CUSTOMERS

We had great support when we had any questions and were able to get in contact with someone at Airfloat to direct us on the right path.

Wildeck

Moves that took 45 minutes are now accomplished in 5.

Automotive Manufacturing

The built-in upenders provide the option to rotate each head to the desired angle, allowing workers more easy access.

Agricultural Assembly

Use of Airfloat equipment resulted in a 50% reduction in the time required for this repair.

Nuclear Energy

Make air caster

tech work for you.

tech work for you.

REQUEST A QUOTE