Assembly Lines

Maximize Performance

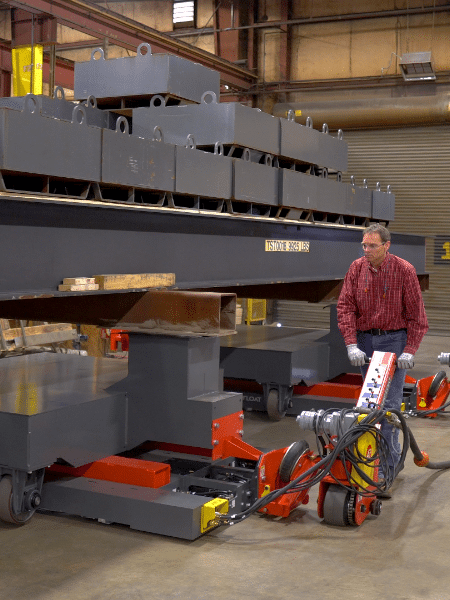

Maximize the performance and functionality of an assembly line system through versatile air caster technology.

Flexibility

Air Caster based assembly solutions don’t require in-ground rails or tow lines, allowing them to be flexible in their placement in your facility.

Friction-Free Movement

Air caster assembly lines offer the omnidirectional movement, requiring less space in your facility.

Investment & Maintenance

Our equipment requires low initial capital investment and minimal maintenance costs, and ends reliance on costly overhead cranes and tow conveyors.

Airfloat and our parent company Align Production Systems deliver flexible automation solutions for fabrication & assembly lines that are easy to implement.

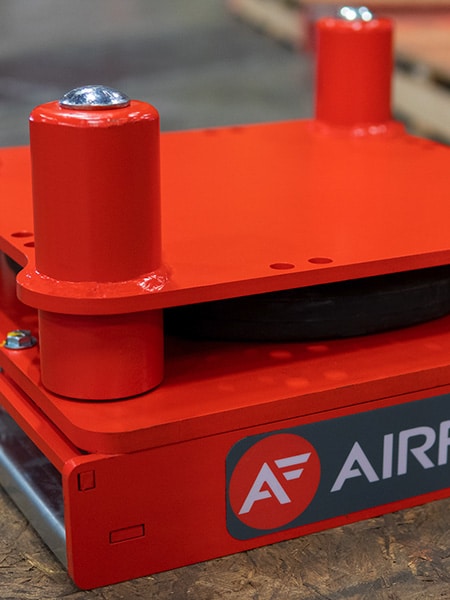

Air Caster Assembly Line solutions offer flexibility and safety that overhead cranes and in-ground conveyor solutions don’t, and don’t require in-ground installation. Our Air Caster assembly line solutions also feature slide-out air caster replacement, reducing downtime to a minimum.